Carrying out the work of safety production standardization is not only basic and important, but also urgent, long-term and overall, which is of great significance. Carrying out the standardization of safety production is the most effective way for enterprises to establish a long-term mechanism for safety production, and to prevent accidents and avoid accountability. The purpose of carrying out the work of safety production standardization is to formulate specific norms and standards in terms of systems, regulations, standards, operations, inspections, etc., and fully implement the main responsibility of enterprise safety production. Since the standardization work regulates each element of the three elements of the enterprise's "human, machine, and environment" safety, there are clear institutional constraints on the entire staff, the entire process, and all aspects of the enterprise's production and operation, which will inevitably effectively reduce the Even prevent accidents, especially major accidents.

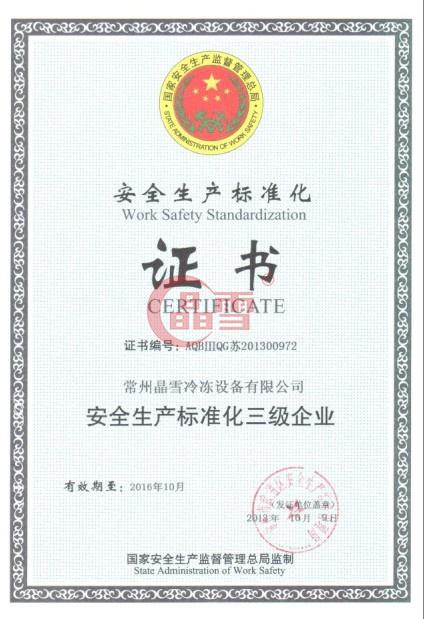

On September 9, the enterprise safety production standardization expert group of Changzhou Wujin District Safety Supervision Bureau, accompanied by relevant leaders, came to the company to conduct on-site inspections. After a comprehensive review by experts, the company successfully passed the third-level acceptance of safety standardization. On the same day, the expert group conducted a comprehensive inspection of the company, and carried out a comprehensive and meticulous acceptance through on-site inspection, information access, consultation and visits, etc. The expert group gave full affirmation and high evaluation to our company's safety production status, and believed that the company attached great importance to safety production work and assigned responsibility to the team, all of which could take the opportunity of safety production standardization and formulate relevant safety production standards. , comprehensively carried out on-site regulation and rectification, further standardized safety management, strengthened safety basic work, and improved the standardization level of safety production. The expert group also pointed out the problems existing in the company's production safety and put forward suggestions for improvement. The company will strictly require higher standards in the future, and strive for greater progress in the work of safety production standardization in the coming year.

About

About Join us

Join us